What Are You Looking For?

What is baffle plates?

The shell side baffle is generally made of Arc-shaped baffle plate. Unless considering pressure drop, pipe vibration, or pipe support and enhanced heat transfer issues, it is required to use a structure without pipes at circular baffles, baffle rods, or arched notches.

Baffles can change the direction of the shell side fluid, making it flow perpendicular to the tube bundle and increasing the flow velocity, thereby increasing the turbulence level of fluid flow and achieving better heat transfer effects.

When the shell side undergoes evaporation, condensation operations, or when the heat transfer film coefficient of the tube side is very low, the effect of the shell side baffle plate is not very obvious, mainly serving as a support for the tube, and sometimes the baffle plate can be omitted; For condensation operations with non condensable gases, using unevenly spaced baffle plates can improve heat transfer efficiency.

(1) The type of baffle

The types of baffle can be divided into arc-shaped baffle, disc annular baffle, orifice baffle, and baffle ring (also known as baffle rod).

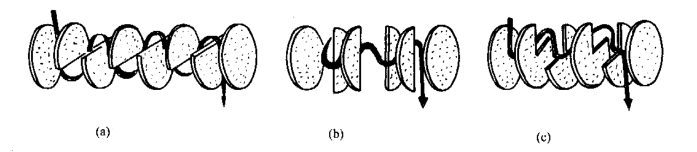

The height of the notch in the arc-shaped baffle can be 10% to 40% of the diameter, and the current common height is 25% of the diameter. In fact, under the same pressure drop, a baffle plate with a defect height of 20% of its diameter will achieve the best heat transfer efficiency. When the flow rate of the heat exchanger is high, in order to achieve better cross flow and avoid fluid induced vibration, the pipe at the notch is often removed, which is called the bow shaped area without pipe layout.

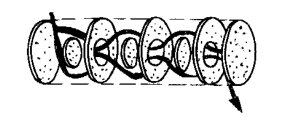

Disc annular baffle plate: The disc annular baffle plate (Figure 2) allows for a large flow rate and low pressure drop, but its heat transfer efficiency is not as good as the arc-shaped baffle plate. Therefore, this type of baffle plate is often used in situations where low pressure drop is required.

Orifice baffle: The orifice baffle (Figure 3) allows fluid to flow through the gap between the baffle hole and the tube, thereby increasing heat transfer efficiency. This type of baffle has a large pressure drop and is only suitable for cleaner fluids.

Baffle rod: It causes the fluid to pass longitudinally through the gap between the baffle rod and the heat exchange tube. This type of heat exchanger requires high flow rate, low pressure drop, and good heat transfer efficiency. Can be used in situations with and without phase transitions.

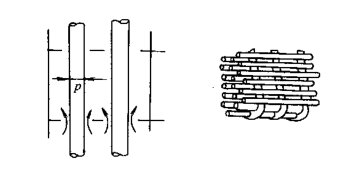

2) Distance between baffle plates

The spacing between baffle plates affects the flow direction and velocity of the shell side fluid, thereby affecting heat transfer efficiency. The minimum baffle spacing should be 1/3 to 1/2 of the shell diameter and should not be less than 50mm. Due to the role of the baffle in supporting the pipe, the maximum baffle spacing for steel pipes without a support plate is 0.74 times the power of 171do (do is the outer diameter of the pipe, measured in mm). If it is necessary to increase the spacing between baffle plates, additional support plates should be installed. If the pipe is made of copper, aluminum or their alloy materials, the maximum unsupported spacing should be 0.74 times the power of 150do.